The Videojet 1860 provides advanced warning of clogging and EHT trips. The new SIMPLICiTYTM interface greatly reduces operator interactions, and the optional VideojetConnectTM Remote Service minimizes the need for on-site service calls.

Performance Without Surprises

Putting the Continuous Into Continuous Inkjet

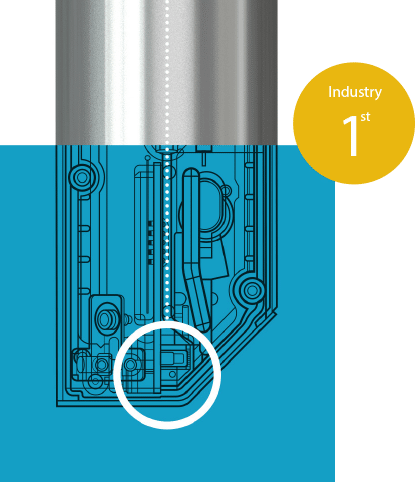

The printer has been designed to deliver industry

first predictive capability providing superior uptime

and performance. The result is a revolutionary design

that achieves your marking and coding objectives

today and as they evolve.

Industry First Predictive Ink Build-up Sensor

Significantly reduce the main cause of unplanned printer

downtime with an industry first ink build-up sensor. The 1860 printhead incorporates a unique sensor which enables the printer to detect build up in the printhead, alerting the user with advanced notification before print

clipping and the associated EHT trips occur.

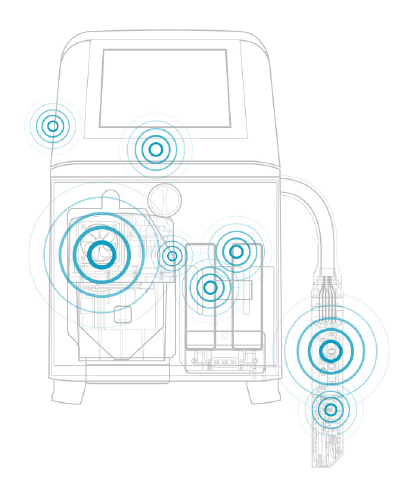

Continuously Monitor Your 1860 Printer’s Health

Powerful on-board intelligence runs through

a revolutionary system, with 53 sensors

continuously monitoring over 150 key indicators

of printer performance, providing expert

diagnostics, analytics and guiding you to

correct problems before they happen.

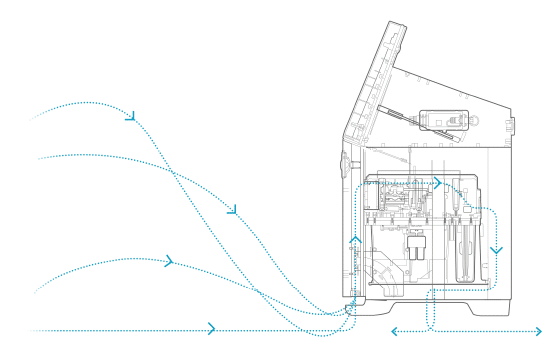

Make Up Reserve Tank With A Minimum 8 Hours of Run Time

An additional reserve tank protects production

under normal operating conditions – allowing ample

advance warning to prevent a downtime event.

Precise fluid transfer measurement increases

the stability of the ink and make-up mix, and

provides reliable indication of remaining fluid

levels. The 1860’s fluid system features a larger

1 litre Smart Cartridge™ with the Videojet

embedded microchip, ensuring only compatible

fluids are used. Loading the wrong ink or an

incompatible make-up fluid is impossible,

helping prevent common operator mistakes.

Natural Fit On Your Line

Meeting The Most Exacting Standards

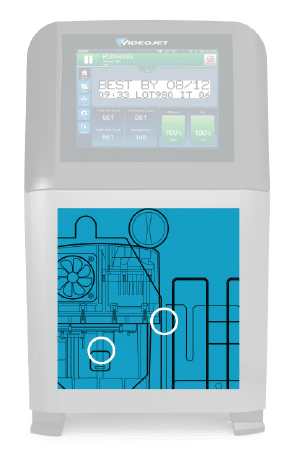

The 1860’s intelligent air flow system directs clean,

cool air to critical components in the printer, extending

the stable operating temperature range to 0-50°C,

even in the most challenging environments.

Driving Down Operational Costs

The 1860 printer is our most efficient yet, with savings

up to 20%* achievable through an innovative approach

to condenser design and solvent recirculation.

Meeting the Most Exacting Standards

The 1860 enables an efficient cleaning operation and faster restart

of your line. Available with optional IP66 rating, hygienic design following industry guidelines incorporates slanted surfaces

that help to prevent fluids or debris build-up, and also help eliminate potential dirt traps.

Available with an optional IP66 rating, eliminates the need to

remove the printer from the line during wash-down.

The 1860 lives on your line in your tough

manufacturing environment.

Minimal Touch Design

Wizards – Guiding You Every Step of the Way

Built-in wizards allow you to customize your interface

to help ensure that your operators only see the options

they need. Error-proofing rules help define editable

fields, permissible data types, date range restrictions

and more, greatly reducing printer interactions and

potential user errors.

SmartCellTM Maintenance Made Simple

Simplify routine maintenance with three color coded.

easy to replace components that can be changed in

just minutes with Videojet SmartCell™ technology.

On-screen alerts provide advance notification,

allowing maintenance to be performed in line

with your production schedules.

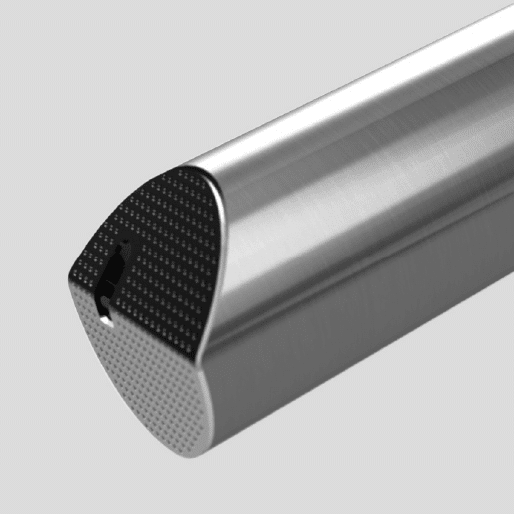

Unique Nozzle Design

The unique design means a cleaner start and print with

longer runs over wide ranges of changing production

conditions. The enhanced Dynamic Calibration™

gives you independent viscosity monitoring and control,

removing the need to wait for the system to get up to

temperature before starting your print job.

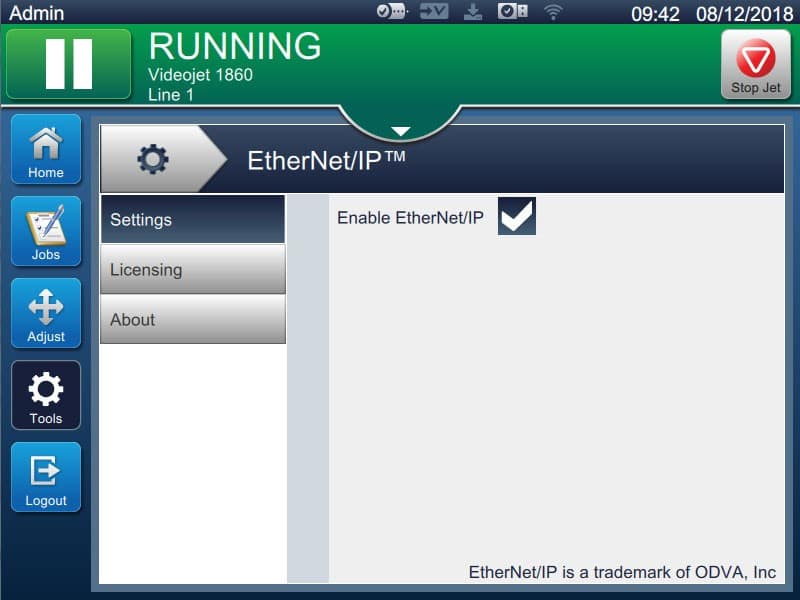

Built-in Evolution

Improve your operations today and tomorrow

The 1860 supports you as your printing needs

change and as your production processes evolve.

New capabilities that expand your printer’s functionality

can be selectively added as you need them.

The scalability of the 1860’s advanced software can make

your printer more productive and profitable as objectives

change. This functionality can make the 1860 the printer

that increases value to your operations over time.

Fine tune your productivity with Videojet LifeCycle AdvantageTM

The 1860’s advanced runtime analytics and reporting will

help ensure continuous improvement. Historical events

from back as far as 90 days can be logged and analyzed.

Optional VideojetConnect™ Remote Service can then

interrogate your performance using easily accessible

drill-down reports.

Specialist Videojet technicians will analyze your comprehensive

data logs and determine the cause and context, enabling you

to reduce future unplanned downtime.